MAST Technologies

A Premium Technology Provider at Competitive Prices

MAST prides itself on the ability to provide premium technology at competitive prices throughout the marketplace. With a spacious elastomer processing suite and full-scale production capabilities, MAST has substantial lab scale development space to rapidly prototype a variety of products.

Certified

Small Business

Military and

Electronics Solutions

Unique Materials,

Tailored Performance,

Uncompromising Requirements

In-House Design

and Development

Intimate

Communication

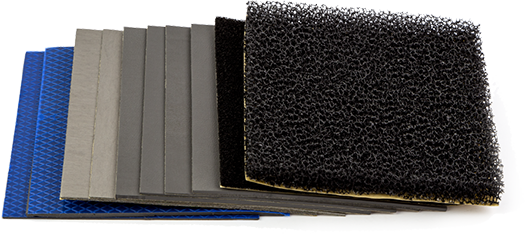

MAST Technologies is equipped with a spacious elastomer processing suite for batch mixing, calendaring, compression molding flat sheets and complex parts, precision sanding, and custom die-cutting.

- Batch mixing via high shear two-roll mill

- Hydraulic Compression Molding Presses with heated plattens

- Precision Grinding

- Die Cutting

MAST Technologies has a versatile coatings and applications sector for mixing and applying liquid coatings via spray and dip processes. MAST’s automated pneumatic spray booth provides optimized and repeatable coating application to a variety of products.

- Ball mill

- Automated spray booth

- Dip tank and laminator

- Production walk-in oven

Microwave Testing

Industry standard microwave measurements can be performed in-house and digital data capture allows for rapid and professional reporting. MAST’s vector network analyzer provides phase and amplitude measurements in a variety of test setups, including microstrip testing, Bistatic Arch Reflectivity, and Insertion Tunnel testing.

Please see Tech Bulletin 101 for more information on the NRL Arch Reflectivity test setup. Surface and volume resistivity measurements of conductive or resistive products are provided by a surface resistivity probe and proper multimeter setup.

Lab Scale Development

In addition to full-scale production, MAST has substantial lab scale development capabilities to rapidly prototype a variety of products.

A one small batch jar roller mill allows for optimization of liquid coating formulations before production in MAST’s production ball mill.

A small oven provides precise temperature control to determine appropriate cure cycles for liquid and solid materials. A lab furnace allows for extended duration heat aging trials.

To determine the flame resistance of products, multiple Bunsen burner test setups have been fabricated to perform UL94 pretesting.

Have More Questions?

For more information about MAST Technologies and our capabilities, contact us today.